Close

Mass production enabled design

scroll down

The market potential for floating offshore wind is huge, but only if floating wind is capable to produce at competitive Levelized Costs of Energy (LCOE) in line with alternative green energy sources. Achieving a competitive cost level requires a highly efficient process from production, transport and installation, and a high turbine efficiency. Economics of scale must be exploited. The wind turbines will therefore increase in size and the number of installed floating units will be high.

This has been the driver of the design of the Moray Base.

In view of mass production, the Moray Base is a most promising design for several reasons

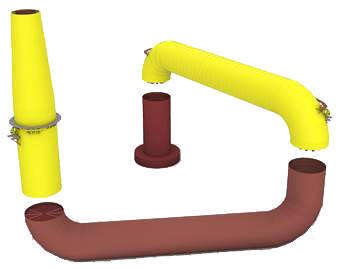

- Production of the sections is industrialized to a high degree. Traditional shipbuilding processes are avoided. A cost effective “monopile fabrication” process is applied for the bulk of the structure. This fabrication process has proven itself for years and for thousands of foundations. Even the elbows can be produced in this way, because they are segmented and build-up from single axis curved plating only;

- Even easier producible elbow connections with Moray Base 2.0

- Simplified global transport of the foundation in 4 sections relies on a large fleet of available general cargo ships. Typical semi-submersible transport vessels, which are limited in availability, are avoided;

- Transport of the sections of Moray 2.0 is even easier since they are all straight and allow for stacking.

- Local content provides the series-assembly of the sections, the turbine erection and farm installation. The assembly is done afloat in a harbour close to the project location with shore based equipment;

- It is highly scalable for future designs of turbines;

- The complete life cycle avoids the use of drydocks, which are expensive, limited in availability and might restrict sizing.

A large scope of local content is anticipated in floater assembly, turbine erection and installation.